Overhaul of helicopters

OVERHAUL STAGES

Helicopter acceptance

Upon acceptance, the helicopter is inspected, the complete set of the helicopter is checked, ground testing of the helicopter systems and its power plant is carried out to assess its technical condition, as well as the analysis of the maintenance records, certificates and log books of the helicopter.

Helicopter dismantling

Helicopter dismantling begins with dismantling the rotor blades and ends with the dismantling of all components, followed by their sorting according to repair areas.

Works on paint removal

Removing the paint is done manually by applying the special solution and processing the parts with crushed fruit kernel in the special pneumatic installation. Cleaning the parts and assemblies of the helicopter from various types of contamination and deposits is carried out in the special flow washing line.

Repair of the helicopter airframe, its removable and non-removable equipment

Repair of the helicopter airframe, its removable (hoods, fillets of outboard tanks, etc.) and non-removable equipment (electric wiring harness, switching equipment, etc.) are carried out in the special hangar and special rooms. During the repair, work is carried out to determine the technical condition of parts and assemblies, to repair and restore their technical condition that meets the technical requirements of the technological and design documentation.

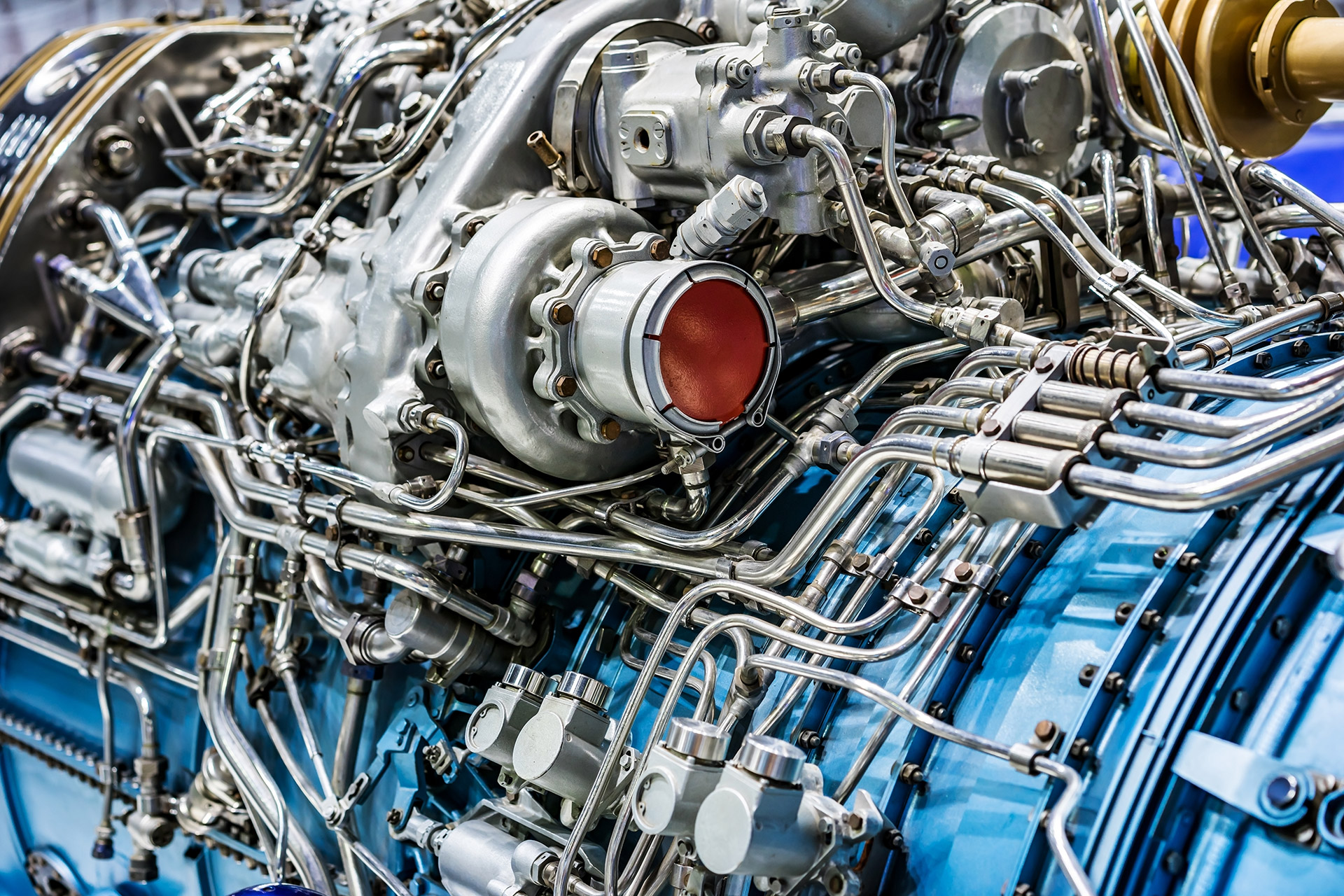

Repair work for helicopter units

In the process of repairing each unit, the following works are carried out:

- dismantling of the unit into parts and assemblies;

- washing, cleaning from contaminations;

- troubleshooting, determination of troubleshooting methods;

- repair, restoration of galvanic coating;

- step by step assembly, adjustment or setting;

- testing, checking parameters for compliance with technical requirements of technological and design documentation;

- building-up with parts and assembly units for installing the unit to the helicopter.

Helicopter assembly works (mounting works)

In the process of assembling the helicopter, a stage-by-stage and operation-by-operation assembly of units and their installation to the fuselage is carried out, as well as adjustment of control parameters, checking of power supply circuits, checking the operability of individual units and parts of the helicopter. The assembly process ends with the procedure for completing the helicopter for ground and flight tests.

Painting of components, assemblies, equipment of the helicopter, and the helicopter as a whole

Ground and flight tests of the helicopter

Ground and flight tests of the helicopter are carried out according to the special program. Strict implementation of all stages of the program allows checking the operability of all helicopter systems and guaranteeing the trouble-free operation of helicopter during the next overhaul and service life. Having completed the flight tests, the helicopter is put into operation with all the necessary documentation.

Aircraft repair and maintenance

Also, the Company may upgrade such aircraft as the Su-25, Su-25UB Aero L-39 Albatros and many others.